Sound proofing and it's technicalities

The gypsum board has a low bending stiffness and a high dead weight, which enhances its sound-absorbing effect. So that the sound insulation can be achieved at the lowest cost.

Soft and flexible mineral wool is used to improve the sound insulation of partitions.In soundproofing, wool is not good for filling the entire body space otherwise the wall will have a swelling effect.For example, when using 66 mm steel profile 50 mm mineral wool is suitable and 66 mm wool is suggested for 95 mm steel profile.

With regard to sound insulation (as opposed to thermal insulation), small gaps can remain between mineral wool strips without affecting the insulation.

Sound insulation in a building

Sound insulation refers to the prevention of sound transmission, which however is not primarily based on sound absorption.Sound insulation is divided into air and step sound insulation.Airborne sound insulation is needed between the two spaces for privacy and noise-free operation.Step-by-step isolation is intended to avoid, for example, disruption caused by movement such as walking.

The goal is to achieve airborne sound insulation between the two rooms, and the sound propagating in the frame is created by the steps in the intermediate floor, which is why step sound insulation is also very important.In many building materials, such as gypsum board, there is a high level of friction loss, and in this case the gypsum board frame sound is quickly suppressed.In a sound wave, media such as air or particles in a building frame move.With each movement, there is friction that reduces the speed of the movement.There is little damping in the air, though if space is taken into account with textiles, mineral wool and foam, the damping is enhanced.

The sound propagates at about 340 m / s if the frequency of the sound is 100 vibrations (100Hz) During one swing the sound propagates at 340/100 = 3.4 m. This is called the wavelength.When sound encounters a solid, solid structure that prevents sound transmission, the motion of air molecules slows down and almost stops in the structure.

Sound absorption

Room noise reduction is needed to improve readability, reduce sound propagation, and reduce sound levels to improve the comfort of your work environment.

Sound levels

Sound pressure is measured in decibel (dB).

Airborne sound insulation

The airborne sound insulation of the walls and floor panels takes into account the fact that the structures reduce the sound pressure exerted on them.The more the structures reduce the sound pressure, the more they isolate the sound.

Impact sound insulation

The sound insulation of the walls and midsoles depends on how well they reduce the noise in the structures.The pitch level is always measured from the adjacent space.The lower the sound level, the better the step-noise isolation.

Soundproofing of steel constructed walls

The plate of the wall depends on the sound insulation of the wall on each side of the plate number, the dimensions of the support structure of the aid, on whether there is a single- or double support frame and the hollow space insulation properties.The more and the heavier the plates used, the better the insulation performance.The larger size of the support frame supports provide greater acoustic insulation, the double frame provides better sound insulation than the simple one and the blank space insulation improves sound insulation, especially in the case of double support structures.In a wall with very good sound insulation, the gypsum boards are located on either side of the double frame structure and the empty space of the frame structure is insulated with mineral wool.

The most common room wall is one with steel frames mounted on specially hardened gypsum boards.The wet space requires a denser steel rail distribution and possible furniture supports.

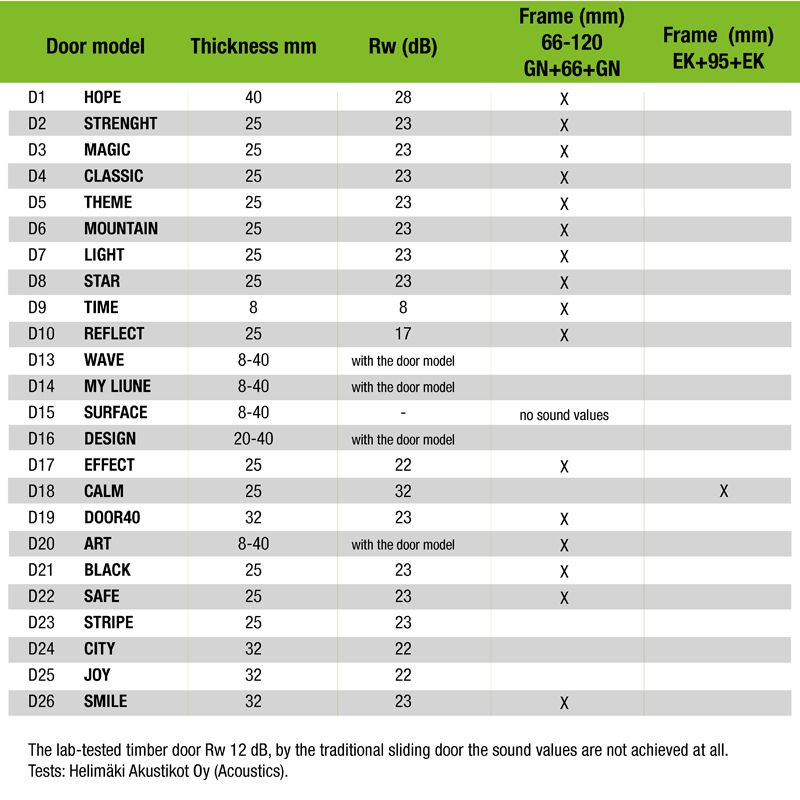

Door sound insulation

A door in the wall reduces the sound insulation of the wall for a number of reasons.The door often has poorer sound insulation properties than the wall structure.The end result depends on the sound categories of the wall and door and the proportion of different sound categories to the area.When using unclassified doors, results are below 25 dB.A still very commonly used hollow extruded 40mm door or wood panel door gives a sound insulation of 12-14 dB, while the 25mm solid Liune door gives 19-22 dB, which means that the Liune door is much more better.

The soundproofing of the wall structure is usually 35-55 dB, because normally the best soundproof wall structures have no doors at all.Doors should always be installed and sealed according to the instructions for sound rated doors.

Holes, gaps and sockets in structures

Each wall outlet that is soundproofed will reduce the soundproofing of the wall.This deterioration can be reduced by sealing the wall outlet with gypsum plaster or mineral wool, or by installing extra plasterboard on the wall.

The significance of the gap or opening in the airborne sound insulation of the wall is considerable.Very small uncompressed gaps affect the insulating properties of the structure.

When carrying out the work, particular attention must be paid to the tightness of the structure and careful construction.For walls with double paneling, the joints should be overlapping with the first paneling.All seams must have a frame behind the seams.Structures should be bonded to door and window frames, stone and panel walls, flooring, columns, beams, etc. so that the joint space is filled with mineral wool or similar material and sealed using suitable sealing compounds.

Specially designed sealing kits (elastic masses), which are generally acrylate latex based and flexible, are used for the sound sealing of small gaps.They make the seam sufficiently airtight, which is the first basic requirement for a sound-proof structure.Soundproofing does not impose special properties on the sealing kit.The most important thing is the good adhesion of the kit and reasonable flexibility.